The Material For Metal Springs

Professional Production: Carbon Steel Springs, Alloy Steel Springs, Stainless Steels Springs, Non-Ferrous Alloys Springs etc.,

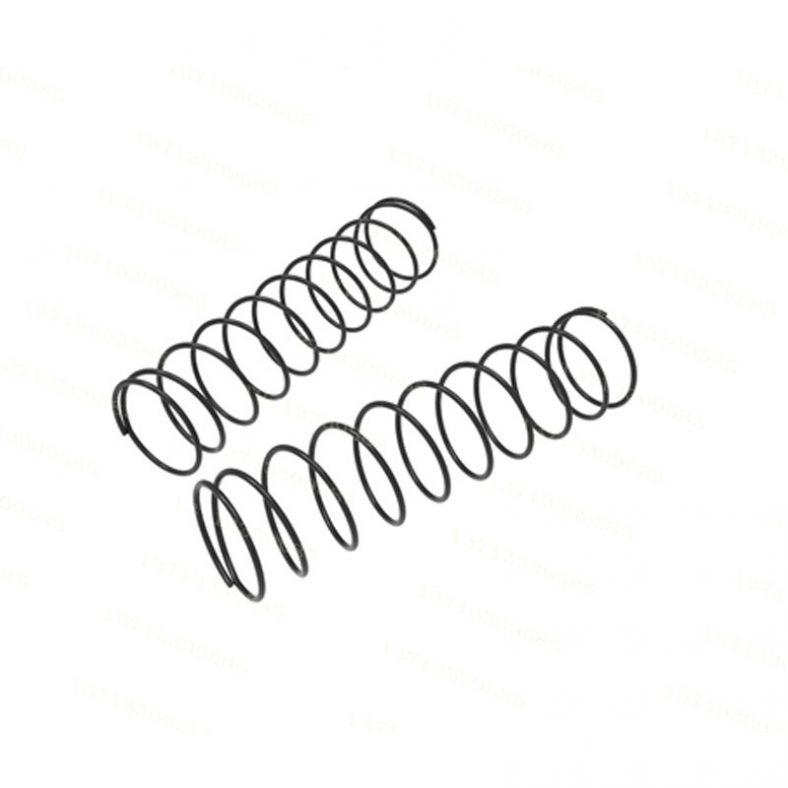

Be-Cu offers a wide selection of metal springs for customized. Metal springs are available in a wide range of material options, characteristics, and price ranges. Selecting the right material for a particular application is an important step when selecting a metal spring. Some considerations related to metal springs are operating temperature, regulatory requirements and corrosion resistance.

Metal springs can be used to manufacture compression springs, extension springs, torsion springs and all types of specialty springs. Be-Cu offers metal springs for sale from stock in music wire, stainless steel, Elgiloy, Oil Tempered MB, Chrome Silicon, and Beryllium Copper. The most common metal spring materials are Music Wire and Stainless Steel. Stainless Steel springs are excellent for corrosion resistance. Be-Cu offers more than 25,000 stock spring designs for sale from inventory or can supply a custom metal spring made to your specifications.

Stainless steel is a type of iron alloy containing 10.5% chromium which is the minimum amount to impart corrosion resistance to the metal. Other alloying elements such as nickel, manganese, and molybdenum are present to enhance its corrosion resistance and mechanical properties. Corrosion resistance is achieved by creating a thin film of metal oxides that acts as protection against corrosive materials. There is a wide array of stainless steel grades available but only a few are used in spring manufacturing.

-

Stainless Steel Alloy Closing Circlip

-

Stainless Steel Alloy Split Circlip

-

Metal Spring For Mobile Phone Holder

-

Spring Locating Pins For Mold Accessories

-

Cnc Turning Stainless Steel Flat Square Shaft

-

Stainless Steel Constant Force Clockwork Spring

-

Special Non-Standard Embedded Stainless Steel Nuts

-

Punching Special-Shaped Spring Sheet

Iron in itself is a soft metal. Alloying it with carbon increases its strength and hardness. Its carbon content can range from 0.05 to 0.30% for mild steels, and 0.30 to 1.70% for high carbon steels that can still respond to heat treatment. Carbon Steel Springs include Music Wire (ASTM A228),Oil-tempered (ASTM A229 Class I and II),Hard-drawn (ASTM 227),High-Carbon Valve Spring Steel (ASTM A230)

Chromium-vanadium steel alloys have the highest quality among the alloy steels in terms of valve spring applications. These are available as annealed, cold-drawn, or oil-tempered wires. Their service temperatures are higher than high-carbon valve springs.Chromium-Silicon Alloy (ASTM A401) are available in cold-drawn or oil-tempered conditions. Chromium-silicon steel alloy can be heat treated to high hardness without losing much ductility.

These are alloys with a base metal other than iron. Common base metals used for spring materials are copper and nickel. Copper alloys generally have high electrical and thermal conductivity, good corrosion resistance, and machinability. Nickel alloys, on the other hand, have superior elevated temperature properties.Non-Ferrous Alloys springs material include Phosphor Bronze (ASTM B159),Beryllium Copper (ASTM B197),Monel 400,Monel K-500,Inconel 600,Inconel X-750 etc