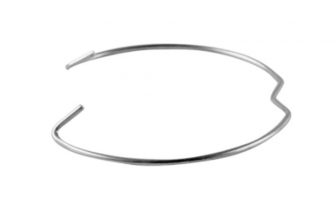

- Spring outer diameter: Custom

- Spring inner diameter: Custom

- Free height: Custom

- Whether standard parts: non-standard parts

- Material: Custom

- Steel wire diameter: Custom

- Pitch: Custom

- Rotation: a variety of options

- Shape: Custom

- Compressive strength limit: Custom

- Surface treatment: on anti-rust oil

- Load: Custom

- Times of use: 50000

- Clamping height: 1.8 (mm)

OEM Stainless Steel Constant Force Clockwork Spring

The constant force spring is made of stainless steel strip, and the high-strength steel strip is shaped by special production spring equipment. When the external force straightens it, the spring will naturally roll back and generate elastic force. However, to achieve our goal is to move. After that, we can return to the starting point we specified.

The constant force spring has the characteristics of maintaining constant force in a long stroke, and can be applied to products that require linear movements such as reciprocating, sliding, stretching, homing, balancing or labor saving. Like we go to common fan lifts, store display shelves, tape measures, sliding doors and windows and computer monitor lifts, etc. Then if you choose a constant force spring that suits your product, there are 8 steps in the design.

- Select Material – Most of the flat steel springs produced by Pintejin are made of type 301 stainless steel. This material is the most accessible and predictable. Pintejin engineers can assist in selecting standard sizes to expedite the process.

- Estimate the life cycle – The life of a constant force spring is very predictable, making it one of the most important considerations. Being realistic is important because longer life cycles are estimated to result in larger, more expensive designs. Underestimating the life cycle of constant force springs can lead to premature failure. Common lifetimes range from 4,000 to about 25,000 lifetimes. If a longer life cycle is required, increased spring diameter and force tolerances due to low stress levels and small differences in materials must be considered.

- Build-up force – The force of the constant force spring should be equal to the requirements of the application. The standard tolerance for constant spring force is ±10%.

- Determine the space——. The inner diameter (ID) of the spring depends on the thickness, life cycle and required force. The outer diameter (OD) depends on the above, with the overall length as an additional consideration. The constant force spring does not extend tangentially to the spring body. Standard tolerance for ID and OD is ± 10%.

- Calculate Overall Length – The overall length of the spring should take into account the actual elongation of the spring in the application, plus at least enough material to hold 1-1/2 turns on the spring at full extension.

- Select End Details – Pintejin has many standard end details available. Pintejin Precision is equipped with a complete tool and die department capable of creating many custom designs required by customers.

- Consider the environment – corrosive atmospheres or extreme temperatures can affect spring life and material selection.

- Complete the design – Once all the above criteria are considered the spring can be located or deduced.

Pintejin high-precision professional production of toughness springs, winding springs, stainless steel plate springs, scroll springs, storage shelf springs, etc.; widely used in a variety of electronic devices, household appliances, small toys, office supplies, Communication equipment, medical machinery, electronic computers, windows and doors, vehicles and other levels, specializing in the production and manufacture of high-precision torsion springs. Using high-quality imported raw materials and domestic raw materials will continue to meet your requirements. We have more than ten years of experience in product development, production and manufacturing, and have become famous brand distributors in China. Our satisfaction is the precondition for our mutual benefit! High-quality goods and excellent service items are your unremitting choices!

Advantages Of OEM Stainless Steel Constant Force Clockwork Spring

- Be-Cu Spring is a hardware spring manufacturer integrating,design and production. With 16 years of rich experience, its products are widely used in various industries such as mechanical equipment and electrical switches.

- Be-Cu Spring has a professional engineering team, and the technical engineer team has an average industry experience of more than 10 years. It focuses on innovative development of green and environmentally friendly products, and is committed to high-quality product quality.

- Focusing on the research and development of the production customization of fatigue-resistant springs, using imported raw materials from Japan, and strictly controlling the low-temperature tempering time in the production process, the service life of springs has increased by more than 20% compared with the same industry.

- Be-Cu Spring has a strict inspection system. Quality inspectors measure various indicators of the product in each process. The yield rate is controlled above 99.8%, and it has obtained international ISO certification.

- The spring has undergone surface strengthening treatment to remove surface impurities, which can make the surface structure stronger, smoother, and rust-proof. The effect is better and the service life of the spring is prolonged.

- The maximum frequency is hundreds of times per minute, suitable for the matching use of high-quality mechanical molds, and can meet the requirements of different customers

Specifications Of Stainless Steel Constant Force Clockwork Spring

| Structural Features | Cylindrical/Barrel/Open at both ends/Shrink at both ends/Conical/Hourglass/Closed at both ends/Both ends are ground/Fixed pitch/Variable pitch/Both ends are not ground |

| Wire Diameter Specification | 0. 08 ~ 8.0mm |

| Surface Treatment | Blackened/Galvanized/Nickel Plated/Shot Peening/Polishing/Dacromet/Anti-rust Oil/Electrolytic Polishing/Teflon Spray/Spray Paint |

| The Uses Of Metal Spring | Multipurpose |

| The Color Of Metal Spring | Customized |

| Lean Manufacturing Processes | Accurate Dynamometers and Projectors for Perfect Size |

| Various Materials | Various Materials To Meet Your Performance Requirements:Carbon Spring Wire SWC / Nickel-plated wire, galvanized wire / Piano wire SWPB / Copper wire, phosphor copper wire, beryllium copper wire / Stainless steel wire SUS301, SUS302, SUS304, SUS316, SUS631 /Square wire, flat wire, semi-circle wire / 65Mn _ / Alloy wire /82B / Other special specification steel wire /55CrSi (SWOSC-V) etc., |

| Firmly Packaged | Strong Packaging Is Not afraid of damage during transportation |