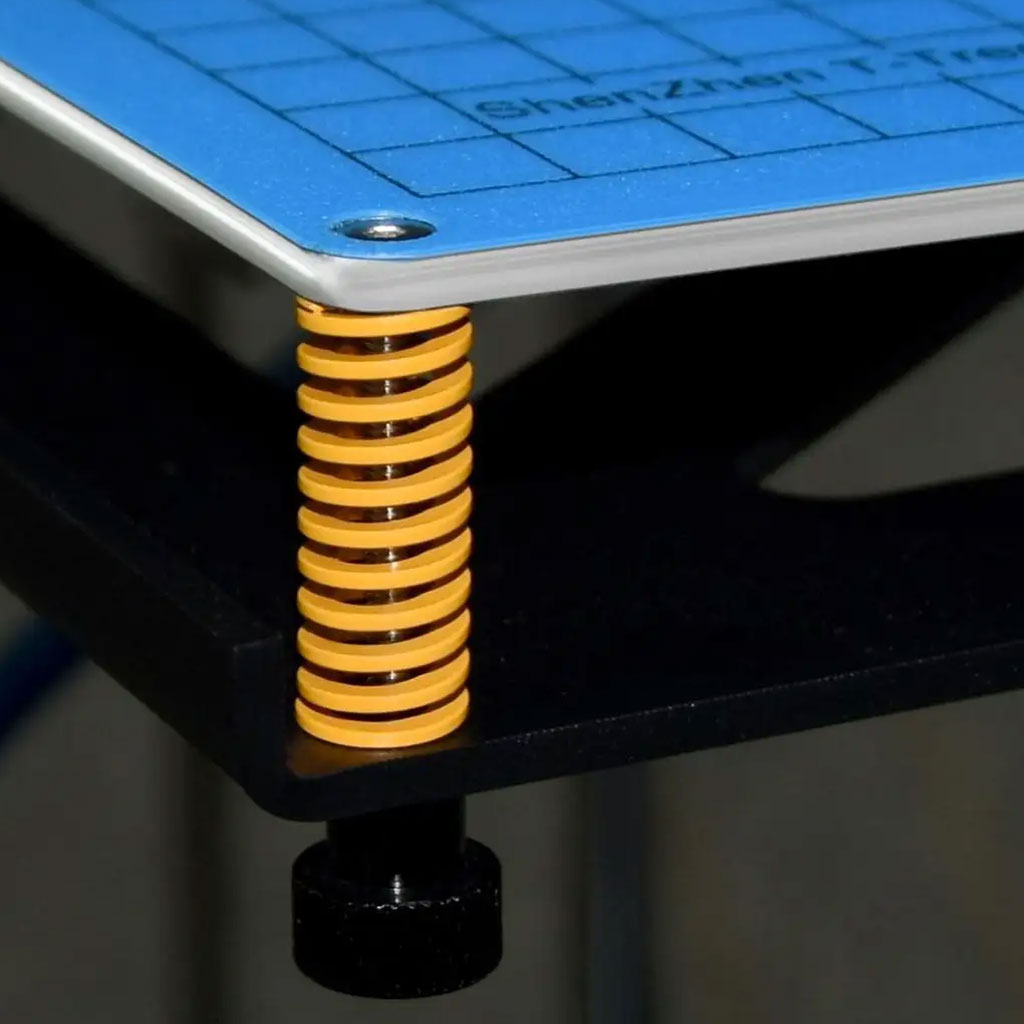

Die Springs

Die springs, also known as rectangular section springs, are also often defined as mold springs.

Die springs have the characteristics of small installation volume, good elasticity, high rigidity, high precision and long fatigue life. Moulds, die-casting molds, plastic molds, casting molds, plastic molds, injection molds, automotive molds, etc…

Standardized die springs produced by Be-Cu Springs mainly refer to: Japanese standard JIS B5012, 6 types (extra light load – silver gray, light load – yellow, light load – blue, medium load – red, heavy load – green, extremely heavy load – Brown); American Standard, 4 types (Light Duty – Blue, Medium Duty – Red, Heavy Duty – Gold, Super Heavy Duty – Green); International ISO 10243 also known as European Standard, 4 types (Light Duty – Green, Medium load – blue, heavy load – red, super heavy load – yellow), a total of fourteen major series, thousands of specifications.

Be-Cu mold springs are produced in a standardized flow, and strict quality inspection ensures that each spring has a good quality assurance and an ideal service life. Similarly, our efficient warehousing and logistics make customers more worry-free and more assured.

The Features And Advantages Of Be-Cu Die Springs

- Material selection: Made of high-quality spring steel (50CrVA). (50CrVA material has high fatigue resistance, high yield ratio and high hardenability)

- Spring structure: rectangular section with rounded corners and rounded edges, with a circular arc inside. (Reduce stress concentration and prolong service life)

- Strong pressure treatment: Be-Cu mold spring has been subjected to strong pressure treatment for more than three times. (To ensure that the permanent plastic deformation of the spring is controlled within a certain range)

- Strengthening treatment: also known as shot peening, the spring surface is strengthened by shot peening. (Make the surface of the spring strong and improve the fatigue strength of the spring)

- Service life: The service life is determined according to the stroke length of the die spring. (The life of P1 is more than one million times, the life of P2 is more than 500,000 times, and the life of P3 is the limit)

Geometry and load tolerance of Be-Cu die spring:

| Outer diameter D(mm) | Inner diameter D (mm) | Free height Ho ≤ 50(mm) | Free height Ho > 50(mm) | Load (N) | Rotation |

|---|---|---|---|---|---|

| 0.0 | +0.7 | ±0.5 | ±1% | ±1% | right |

Die Spring Installation And Use

Be-Cu Die Spring Installation:

- When installed in a flat bottomed hole without a guide rod, the depth of the hole must be at least flush with the second turn of the die spring.

- When installed in an environment with a guide rod, the length of the guide rod must be greater than the length of the die spring.

Precautions For The Use Of Be-Cu Mold Spring:

- In order to prevent bending deformation, it is necessary to guide the die spring.

- In order to prevent damage caused by foreign objects caught in the working die spring, be sure to pay attention to the working environment.

- To prevent damage from repeated shock compression, it is important to use the initial amount of compression as much as possible.

- The installation surface of the die spring must be flat, and the spring axis should be perpendicular to the installation surface to avoid unnecessary damage caused by eccentric load.

- When the die spring is used inside and outside, the die spring will be worn or even directly damaged due to the relationship between the internal and external interference.

- When the mold springs are used in series, due to the instability of the contact surface, it is very easy to bend and deform, and it is also easy to cause damage.

Round section or special-shaped section (square, rectangular, flat and S, D, S, etc.) steel wire cylindrical helical compression springs, rubber (neoprene and urethane rubber) springs, gas-filled springs and disc springs in different types of There are applications in the mold. However, from the perspective of application scope and quantity: the circular section steel wire coil spring is declining, the special-shaped section steel wire especially the flat and S, D, S-shaped steel wire cylindrical coil spring is increasing, and the rubber spring, especially the polyurethane rubber spring, tends to be stable. There has been an increase, while disc springs and nitrogen-filled springs are still in the trial stage of small batches. It seems that there is a certain market. However, if the application prospects of springs are comprehensively evaluated in terms of static and dynamic characteristics, serviceability and economy, it remains to be practiced. later on.

The Classification Of Die Springs

Die springs – generally speaking, they are springs used in molds. The mold springs we talk about are divided into three categories: metal coil springs, nitrogen gas springs, and polyurethane springs.

Metal Coil Die Spring

Metal spiral die springs are widely used in molds, fixtures, industrial clutches, brake components and various mechanical components.

Japanese standard spring classification: super heavy load DB brown mold spring, heavy load DH green mold spring, medium load DM red mold spring, light load DL blue mold spring, light load DF yellow mold spring, etc.

International standard classification: SJL green die spring, SJM blue die spring, SJH red die spring, SJB yellow die spring, etc.

Gas Spring

The internal manufacturing quality has reached the international standard, and the price is about 50% lower. It can be exchanged with the nitrogen gas springs of Dadco, Kaller, Misumi, Hyson, Boding, Quiri and other brands, and the delivery time is short and the service is fast.

Spring classification: Mc-ISO international standard type, MQk-structure compact type, MQa-super compact type, MQHl-extra thin structure type.

Polyurethane Spring

Polyurethane spring classification: EX type high load polyurethane spring, A type high load polyurethane spring, LA type high load polyurethane spring, UT type high load polyurethane spring, UD type high load polyurethane spring Wait.