Shape memory alloys (SMAs) have long captivated engineers and scientists with their remarkable ability to “remember” and revert to a predefined shape after undergoing significant deformation. This unique property, rooted in a reversible phase transformation between austenite and martensite structures, opens doors to innovative applications in adaptive structures, particularly in the realm of spring designs. Traditional springs, crafted from conventional metals like steel or titanium, offer reliable elasticity but lack the intelligence to adapt to environmental changes such as temperature fluctuations or mechanical stresses. In contrast, SMA-based springs can dynamically adjust their stiffness, length, or curvature, making them ideal for next-generation systems in aerospace, biomedical devices, robotics, and civil engineering.

The resurgence of interest in SMAs stems from recent advancements in material processing, computational modeling, and integration with other smart materials. For instance, the development of high-temperature SMAs (HTSMAs) capable of operating beyond 100°C has expanded their utility in harsh environments, while precision fabrication techniques like photochemical etching have enabled intricate microstructures essential for miniature adaptive springs. This article delves deeply into these progresses, drawing from a wealth of recent literature and experimental data to explore how SMAs are revolutionizing spring designs. We will examine the foundational principles, fabrication challenges, design paradigms, and real-world implementations, culminating in a forward-looking assessment of challenges and opportunities.

At its core, the adaptive spring—whether a coiled wire actuator or a lattice network—leverages the shape memory effect (SME) to provide not just recovery but proactive response. Imagine a helicopter rotor blade where embedded SMA springs morph the trailing edge to optimize lift under varying flight conditions, or a prosthetic limb that stiffens intuitively with user movement. These are no longer speculative; they are grounded in prototypes tested in labs from NASA to European universities. As we navigate through the sections ahead, we’ll uncover the technical intricacies that make such feats possible, supported by comparative tables that highlight SMA springs’ superiority over legacy materials.

Section 1: Fundamentals of Shape Memory Alloys

1.1 The Shape Memory Effect: A Phase Transformation Marvel

The shape memory effect in alloys like nickel-titanium (NiTi, or Nitinol) arises from a diffusionless, martensitic phase transformation that allows the material to undergo large deformations—up to 8% strain—and recover upon heating. In the low-temperature martensite phase, the crystal lattice is twinned, enabling easy detwinning under stress without permanent damage. Heating triggers the reverse transformation to the high-temperature austenite phase, where the rigid lattice snaps back to its original configuration. This isn’t mere elasticity; it’s a thermodynamic dance governed by critical temperatures: martensite start (M_s), martensite finish (M_f), austenite start (A_s), and austenite finish (A_f).

For adaptive spring designs, this effect is pivotal. A coiled SMA spring, compressed in its martensitic state, can extend dramatically when heated, acting as a thermal actuator. Hysteresis—the temperature gap between forward and reverse transformations—typically spans 20-40°C, which designers exploit for stable two-way memory after training cycles. Recent studies emphasize tuning these temperatures via alloying; for example, adding hafnium to NiTi raises A_f to 150°C, suiting aerospace applications where ambient heat from engines can drive actuation without external power. This tunability transforms passive springs into sensors-actuators hybrids, responding to both mechanical load and thermal cues.

Consider the microstructure: in martensite, variants align under stress, creating detwinned structures that store elastic energy. Upon austenitization, atomic shuffling realigns the lattice, releasing this energy as macroscopic recovery. Fatigue limits this to about 10^4-10^5 cycles at 4% strain, but advancements in grain refinement via severe plastic deformation have pushed this to 10^6 cycles, crucial for cyclic loading in adaptive springs.

1.2 Superelasticity: The Pseudoelastic Companion

Complementing SME is superelasticity, or pseudoelasticity, where SMAs recover strains up to 10% isothermally via stress-induced martensite formation above A_f. In a stress-strain curve, this manifests as a plateau where austenite transforms to martensite at constant stress (around 400-600 MPa for NiTi), followed by elastic unloading that reverts the phase. For springs, this means absorbing shocks without permanent set—ideal for vibration damping in automotive suspensions or biomedical stents.

In adaptive designs, superelastic SMA coils provide tunable damping: under low loads, they behave elastically; at higher stresses, the plateau dissipates energy through hysteresis loops. Elastocaloric effects further enhance this, as phase changes absorb/release heat, enabling cooling applications in spring-integrated heat exchangers. Comparisons with traditional elastomers show SMAs offering 5-10 times the energy density, though with slower recovery times (seconds vs. milliseconds).

1.3 Common SMA Compositions and Their Trade-offs

NiTi dominates due to biocompatibility and ease of processing, but alternatives like Cu-based (Cu-Al-Ni) or Fe-based (Fe-Mn-Si) alloys offer cost savings for large-scale springs. NiTi’s transformation temperatures range from -100°C to 100°C, with superelastic variants tuned below room temperature for biomedical use. Cu alloys provide two-way SME without training but suffer corrosion; Fe alloys excel in welding but lag in fatigue life.

A comparative table of key compositions, drawn from aerospace-focused reviews, underscores these differences:

| Alloy Type | Transformation Temp Range (°C) | Max Recoverable Strain (%) | Fatigue Cycles (at 4% strain) | Cost Relative to NiTi | Key Application in Springs |

|---|---|---|---|---|---|

| NiTi (Nitinol) | -50 to 100 | 8 | 10^5 – 10^6 | Baseline | Biomedical actuators, aerospace morphing |

| NiTiHf (HTSMA) | 50 to 180 | 6 | 10^4 | 1.2x | High-temp engine components |

| Cu-Al-Ni | -150 to 200 | 5 | 10^4 | 0.6x | Low-cost vibration isolators |

| Fe-Mn-Si | -200 to 200 | 4 | 10^3 | 0.4x | Civil engineering braces |

| Ni-Mn-Ga (Magnetic SMA) | -50 to 50 | 10 (under magnetic field) | 10^6 | 1.5x | Rapid-response robotic springs |

This table highlights NiTi’s versatility for adaptive springs, balancing strain recovery with durability.

Section 2: Historical Development of SMA Springs

2.1 From Discovery to Early Applications

The SMA journey began in 1932 with Ölander’s observation of gold-cadmium’s SME, but practical springs emerged post-1960s with Buehler’s NiTi invention at the U.S. Naval Ordnance Lab. Early 1970s saw SMA wires in eyeglass frames and pipe couplers, evolving to coiled springs for actuators by the 1980s. NASA’s 1990s experiments with SMA strings for adaptive antennas marked a pivot to structural integration, where springs compensated for thermal distortions in space reflectors.

By the 2000s, DARPA’s Smart Wing program deployed SMA torque tube springs for 61% improved roll control, outpacing hydraulic alternatives. This era’s focus on miniaturization led to etched SMA films for MEMS springs, blending etching precision with SME.

2.2 Milestones in Adaptive Spring Innovation

The 2010s brought hybrid designs: SMA springs antagonized by elastomeric biases for reversibility, as in Delft University’s morphing networks. 2020s advancements include 4D-printed SMA lattices, where springs self-assemble under heat, and magnetic SMAs for field-driven actuation. A timeline of key milestones:

- 1963: NiTi patented.

- 1995: NASA SMA antenna tests (6 mm stroke, 87 N force).

- 2003: Electrochemical etching refined for SMA microstructures.

- 2018: Bistable SMA spring actuators with 115 N output.

- 2025: Photochemical etching yields for Nitinol sheets hit 95% efficiency.

These steps have democratized SMA springs, shifting from lab curiosities to commercial viability.

Section 3: Material Properties and Characterization

3.1 Thermomechanical Properties

SMA springs’ efficacy hinges on properties like Young’s modulus (28-75 GPa in martensite/austenite) and transformation stresses (200-600 MPa). Damping capacity, quantified by loss factor tan δ, reaches 0.1-0.2, dwarfing steel’s 0.01. Thermal conductivity (7-18 W/m·K) poses cooling challenges but enables passive actuation via ambient heat.

Characterization employs DSC for transformation temps, tensile tests per ASTM F2516 for plateaus, and bend-free recovery for Active A_f. Cyclic loading reveals functional fatigue, with strain recovery dropping 20% after 10^4 cycles unless mitigated by heat treatments.

3.2 Corrosion and Biocompatibility

In biomedical adaptive springs, NiTi’s passivation layer ensures <0.1 ppm Ni release, outperforming Co-Cr alloys. Etching introduces surface oxides that enhance corrosion resistance in saline, per potentiodynamic polarization tests showing pitting potentials >800 mV.

3.3 Advanced Properties: Elastocaloric and Magnetic Effects

Elastocaloric cooling in superelastic springs absorbs 20 J/kg·K under cycling, rivaling vapor-compression. Magnetic SMAs like Ni-Mn-Ga offer 1 kHz response, ideal for high-frequency vibration control.

A detailed property table for spring-relevant metrics:

| Property | NiTi Spring | Steel Spring | Elastomer Spring | Notes |

|---|---|---|---|---|

| Recoverable Strain (%) | 6-8 | 0.5-1 | 100-400 | SMA for moderate, controlled recovery |

| Energy Density (J/cm³) | 10^7 | 10^6 | 10^5 | SMA excels in compact designs |

| Response Time (s) | 1-10 | <0.1 | 0.01-1 | Trade-off for thermal actuation |

| Fatigue Life (cycles) | 10^5 | 10^7 | 10^4 | Improved via alloying |

| Corrosion Rate (mm/year) | 0.001 | 0.01 | N/A | SMA superior in harsh environments |

Data aggregated from recent reviews.

Section 4: Fabrication Techniques for SMA Springs

4.1 Conventional Processing: Drawing and Coiling

SMA wire drawing reduces diameter to 0.05-2 mm, followed by coiling on mandrels and shape-setting anneals at 400-500°C. For adaptive springs, bias springs integrate during coiling, ensuring two-way recovery.

4.2 Advanced Manufacturing: Additive and Etching Methods

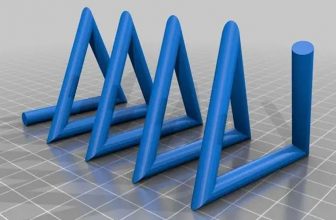

Additive manufacturing (AM) like LPBF fabricates porous SMA lattices with 95% density retention, enabling springs with embedded sensors. Directed energy deposition suits large coils, preserving SME via in-situ heat control.

Metal etching, particularly for microstructures, has advanced significantly. Electrochemical etching uses inorganic salt-alcohol electrolytes (e.g., NaCl in methanol) at 5-10 V, achieving 10 μm/min etch rates on NiTi without intermetallics. Photochemical etching, per Johnson Matthey’s 2015-2025 refinements, employs ferric chloride for Nitinol sheets, yielding burr-free edges and 95% material utilization—vital for cost-sensitive adaptive designs. This technique etches complex spring geometries, like auxetic patterns, enhancing strain amplification by 57%.

Comparative etching table:

| Technique | Etch Rate (μm/min) | Surface Finish (Ra, μm) | Suitability for Springs | Cost |

|---|---|---|---|---|

| Electrochemical | 5-15 | 0.5-1 | High (precise wires) | Low |

| Photochemical | 2-8 | 0.1-0.3 | Very High (sheets/lattices) | Medium |

| Laser Ablation | 10-50 | 1-2 | Medium (thermal damage risk) | High |

| Wet Chemical | 1-5 | 0.3-0.8 | Low (isotropic) | Low |

Etching enables hybrid springs with micro-features for better heat transfer.

4.3 Heat Treatment and Training Protocols

Post-fabrication annealing sets A_f, while training (10-100 cycles of deformation-heat) induces two-way SME, boosting recovery by 4%. For springs, this yields 20% force consistency across cycles.

Section 5: Design Principles for Adaptive Springs

5.1 Kinematic and Structural Modeling

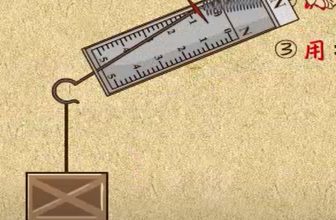

Designing adaptive springs requires balancing actuation stroke, force, and bandwidth. Kinematic models treat springs as beam elements with phase-dependent stiffness, using Euler-Bernoulli theory for coil deflection: δ = (F L^3)/(3 E I), where E varies by phase.

For networks, conformal mapping prescribes nonuniform strain for Gaussian curvature, as in Delft’s prototypes achieving double-curved morphing from flat lattices. Antagonist biases (elastomers or opposing SMAs) ensure reversibility, with stiffness ratios >5:1 for stability.

5.2 Integration with Composites and Textiles

Embedding SMA springs in GFRP composites yields morphing wings with 13% L/D gains. In textiles, like ADAPTEX facades, 3-5% contraction buckles fabrics for shading, self-regulating via solar heat.

5.3 Scaling from Micro to Macro

Micro-springs (50 μm wire) suit MEMS, with 1 mm strokes; macro versions (2 mm wire) deliver 100 N in actuators. Scaling laws predict force ~ wire diameter^4, guiding designs.

Section 6: Advances in SMA Spring Designs

6.1 Aerospace Applications: Morphing and Damping

SMA springs shine in aerospace, where variable geometry chevrons (VGC) reduce jet noise by 3 dB via temperature-driven morphing, saving 2-3% fuel. Boeing’s ecoDemonstrator uses SMA coil springs for vortex generators, cutting drag 5%. In antennas, strings act as perimeter springs, steering beams with 0.39 dB loss at 20% strain.

Bistable actuators with dual SMA springs achieve 5 mm strokes at 115 N, 40% lighter than hydraulics. Table of aerospace metrics:

| Design | Stroke (mm) | Force (N) | Response Time (s) | Weight Savings (%) |

|---|---|---|---|---|

| VGC | 20 | 50 | 5 | 30 |

| Morphing Wing Spring | 10 | 87 | 3 | 25 |

| Antenna String | 6 | 90 | 10 | 15 |

| Bistable Actuator | 5 | 115 | 3 (at 30A) | 40 |

6.2 Biomedical Innovations: Prosthetics and Implants

In prosthetics, SMA springs in knee orthotics provide adaptive stiffness, mimicking muscle via 4% strain recovery. Stents use superelastic coils expanding 100% post-deployment. Adaptive lenses employ wire “springs” bending glass for 2.4 diopter shifts, focusing lasers with 0.75 mm deflections.

6.3 Robotics and Civil Engineering

Robotic grippers with SMA torsion springs handle delicate objects at 3600 m depths, corrosion-free. Civil braces dissipate seismic energy via 7% strain, reducing building sway 50%.

6.4 Emerging Hybrids: Magnetic and 4D-Printed Springs

Ni-Mn-Ga springs respond in ms to fields, for soft robots. 4D-printed versions self-morph into auxetic springs, amplifying strain 57%.

Section 7: Numerical Simulations and Modeling

7.1 Constitutive Models: Brinson and Beyond

Brinson’s model, implemented in Abaqus UMAT, simulates phase fractions ξ via cosine kinetics, predicting spring recovery with 92% accuracy at 110°C. For networks, FEM with BEAM188 elements forecasts buckling, though overestimating deflection by 20% due to strain-varying stiffness.

7.2 Finite Element Applications

Simulations of bistable actuators reveal 20 MPa von Mises stress peaks, guiding etch-optimized geometries. Isogeometric analysis in facades optimizes openness factors to 70%.

Section 8: Experimental Evaluations

8.1 Actuation Tests and Performance Metrics

Delft prototypes deform 21 mm struts into S-curves at 1.7 W, but local buckling limits smoothness. NASA tests confirm 3.28 dB gain shifts in antennas via 40% actuation.

8.2 Durability and Fatigue Studies

Cyclic tests show 10^5 cycles at 4% strain before 20% degradation, improvable to 10^6 via Hf doping.

Section 9: Comparative Analysis

9.1 SMA vs. Traditional and Alternative Smart Materials

SMA springs outperform in force density but lag in speed. Vs. piezoelectrics: SMAs offer larger strokes (8% vs. 0.1%), lower voltage (Joule heat vs. kV).

Extended comparison table:

| Material | Stroke (%) | Force Density (MPa) | Bandwidth (Hz) | Cost ($/kg) | Applications |

|---|---|---|---|---|---|

| SMA Spring | 6-8 | 200-600 | 0.1-1 | 500-1000 | Adaptive morphing |

| Steel Spring | 0.5 | 1000 | >100 | 5 | Static loads |

| Piezo Spring | 0.1 | 50 | 1000 | 2000 | Precision vibration |

| SMP Spring | 200 | 1 | 0.01 | 50 | Large deformation |

| Magnetic SMA | 10 | 100 | 1000 | 1500 | Fast robotics |

Data from multi-sector reviews.

9.2 Etching Techniques Comparison

As detailed in Section 4, photochemical etching leads for precision in adaptive designs.

Section 10: Challenges and Future Directions

Fatigue after 10^5 cycles, slow cooling (10-40 s), and $500/kg costs hinder scaling. Hysteresis causes 10-20% energy loss.

Future lies in SMA-piezo hybrids for ms responses, AI-driven FEA for custom designs, and sustainable Fe-SMAs at $200/kg. Market projections: $45B by 2033, with springs capturing 30%. Research gaps include cryogenic SMAs for space and bio-resorbable variants.

Advances in SMAs have elevated adaptive spring designs from niche experiments to transformative technologies, enabling structures that sense, actuate, and heal. From etched microstructures to simulated networks, the field is poised for exponential growth, promising lighter, smarter systems across industries. As we refine models and processes, SMA springs will undoubtedly spring forth new engineering paradigms.