Torsion springs are vital components in various mechanical and industrial applications, where they provide rotational force or torque by twisting around an axis. Accurate measurement of torsion springs is crucial for ensuring proper fit, functionality, and performance in machinery and devices. This comprehensive guide aims to provide a detailed, step-by-step approach to measuring torsion springs accurately.

Understanding Torsion Springs

Before delving into measurement techniques, it’s essential to grasp the basic principles of torsion springs. These springs store mechanical energy when twisted, exerting torque in proportion to the applied angular displacement. Typically made from hardened steel or other metals, they come in various shapes and sizes to suit different applications.

Tools Required for Measurement

To accurately measure torsion springs, you will need several tools:

- Caliper: For precise measurement of wire diameter and coil dimensions.

- Micrometer: To measure the spring’s body diameter accurately.

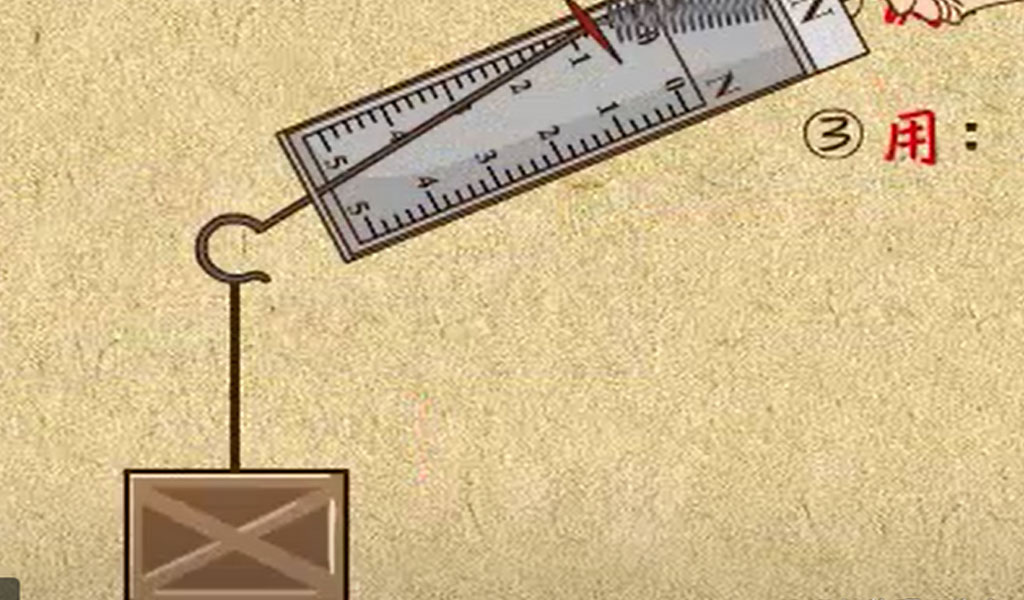

- Spring Gauge: Specifically designed to measure spring rate and torque.

- Angle Gauge: Used to determine angular deflection and twist.

- Scale or Balance: For measuring the spring’s weight, which affects torque calculations.

- Safety Equipment: Gloves and eye protection, especially for handling tensioned springs.

Step-by-Step Measurement Process

Step 1: Measure Wire Diameter

Using a caliper, measure the diameter of the spring wire. Take several measurements at different points to account for any variations. Record the average diameter.

Step 2: Determine Spring Diameter

Use a micrometer to measure the outer diameter of the spring body. Ensure the calipers are perpendicular to the axis of the spring to avoid skewed measurements.

Step 3: Count the Number of Coils

Count the total number of active coils on the spring. An active coil is one that contributes to the spring’s deflection and torque generation.

Step 4: Calculate Spring Rate

Use a spring gauge to measure the force required to twist the spring through a known angle (typically 90 degrees). The spring rate, or torque per unit angle, can be calculated using the formula:

K=T/θ

Where K is the spring rate, T is the torque, and θ is the angle of twist.

Step 5: Measure Free Length

- Measure the length of the spring when it is not under load (free length). This measurement is crucial for determining the initial tension and deflection characteristics of the spring.

Step 6: Calculate Initial Tension

Initial tension is the force exerted by the spring when in its unloaded state. It can be calculated using the formula:

F0=G⋅D/4⋅L

Where F0 is the initial tension, GGG is the modulus of rigidity of the spring material, DDD is the wire diameter, and LLL is the free length of the spring.

Step 7: Verify Specifications

- Compare the measured parameters (wire diameter, spring diameter, number of coils, spring rate, free length, and initial tension) with the manufacturer’s specifications or engineering drawings to ensure compliance.

Tips for Accurate Measurement

- Consistency: Ensure measurements are taken consistently and at predefined points across the spring.

- Precision: Use high-quality measuring tools calibrated to the appropriate standards.

- Safety: Exercise caution when handling tensioned springs to prevent injury.

Conclusion

Accurate measurement of torsion springs is essential for maintaining performance and safety in mechanical systems. By following the step-by-step guide outlined above and utilizing appropriate tools and techniques, engineers and technicians can ensure that torsion springs meet design specifications and perform reliably in their intended applications.

References

- Machinery’s Handbook, 30th Edition.

- ASM Handbook: Volume 14B, Metal Working: Sheet Forming.

- Engineering Toolbox: Torsion Springs.

This guide provides a foundational understanding and practical approach to measuring torsion springs accurately, supporting the efficient operation of mechanical devices across various industries.