- Spring outer diameter: Custom

- Spring inner diameter: Custom

- Free height: Custom

- Whether standard parts: non-standard parts

- Material: Custom

- Steel wire diameter: Custom

- Pitch: Custom

- Rotation: a variety of options

- Shape: Custom

- Compressive strength limit: Custom

- Surface treatment: on anti-rust oil

- Load: Custom

- Times of use: 50000

- Clamping height: 1.8 (mm)

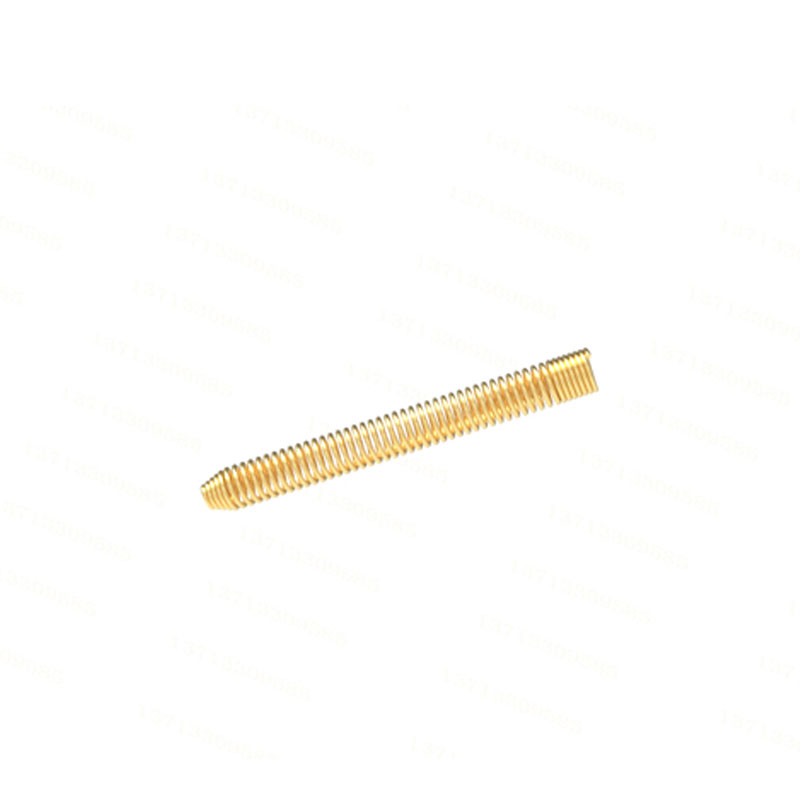

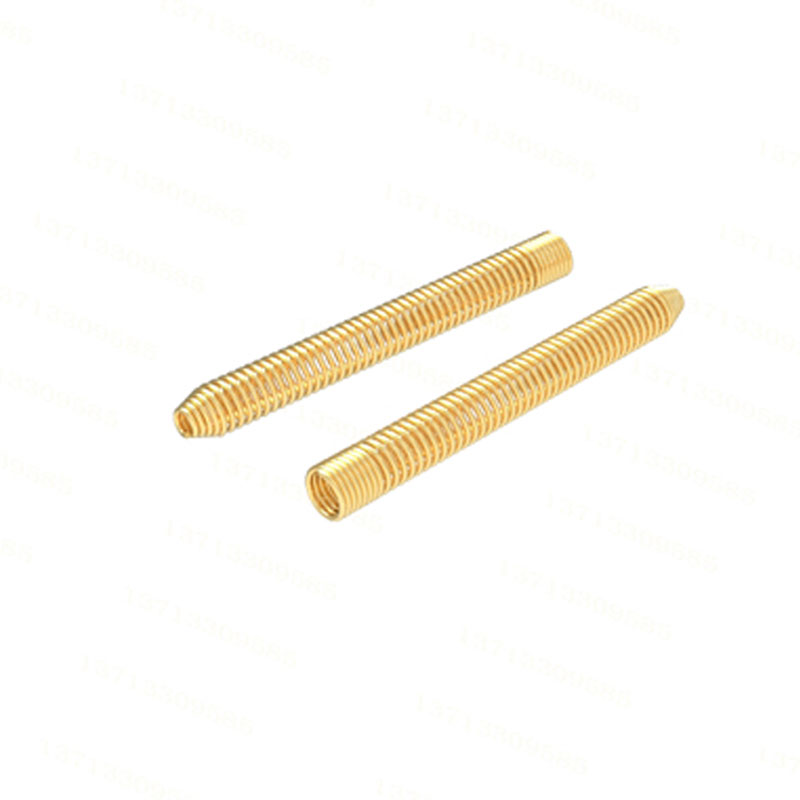

OEM Beryllium Copper Precision Springs For Probe

The spring probe needle material is generally selected as Becu or SK. Both have advantages and disadvantages. Becu has good conductivity, but lacks hardness, and SK has high hardness, but it is easy to rust. The choice of spring probe spring material is also more important. SUS SWP, especially now more and more PB free products, directly lead to the pins or BGA solder balls becoming soft or hard. During the test, it was found that the original The yield is very high. After changing the solder ball or lead material, the yield is extremely poor. The choice of spring pressure is very important. The test environment has very strict requirements on the material of the spring. The high and low temperature test directly affects the work of the spring probe. life. Today, Spring Home Jinxi Spring takes us to understand what are the advantages of high-quality probe springs?

- Good contact reliability: The spring probe has a larger amount of compression than the shrapnel connector of the same size, and the contact is more stable. When it is strongly impacted by external force, the spring pressure change of the spring probe is relatively small.

- It can effectively save the space of the PCB board: under the same amount of compression, the spring probe takes up less space than the shrapnel connector.

- The contact point is more stable: the contact point of the spring probe does not move when it is compressed, while the shrapnel connector will move relatively. The stable contact point can make the product obtain stable electrical performance and better exert the performance of the product .

- Longer service life: The spring probe can be retracted at least 10,000 times, and the spring probe with better quality can be retracted more than 100,000 times, which also makes the service life of the product longer.

- The production speed is fast and the cost is low: the spring probe does not require mold opening and stamping, and the development sample and mass production time is short, so the spring probe is a more economical and faster connector selection method. With the continuous development of the industry, the products that precision springs are in contact with us are appearing more and more frequently. So what is the main function of precision springs?

- Control the movement of machinery, such as valve springs in internal combustion engines, control precision springs in clutches, etc.

- Absorb vibration and impact energy, such as buffering precision springs under automobiles and train carriages, vibration-absorbing precision springs in couplings, etc.

- Store and output energy as power, such as precision springs in precision springs of watches and clocks.

- Used as a force measuring element, such as a force measuring device, a precision spring in a precision spring balance, etc. The ratio of the load to the deformation of the precision spring is called the spring stiffness. The higher the stiffness, the harder the precision spring. Precision spring is an elastic element widely used in the mechanical and electronic industries. Precision spring can produce large elastic deformation when loaded, convert mechanical work or kinetic energy into deformation energy, and the deformation of the spring disappears and returns to its original state after unloading. , which converts deformation energy into mechanical work or kinetic energy.

Pintejin is a modern enterprise specializing in the production of various types of fine springs. It has been committed to the development and research of high-quality spring products. The minimum outer diameter of the production springs starts from 0.35. With advanced production technology and equipment at home and abroad, it has laid a solid foundation for ensuring product quality. At the same time, it has a high-quality testing and production management team, skilled production workers, and a perfect quality assurance system. Everything follows standardized and humanized management, and long-term focus on product quality and high-quality service, so that the company can continue to grow and develop. You are welcome to come to consult or contact [email protected]

Advantages Of OEM Beryllium Copper Precision Springs

- Be-Cu Spring is a hardware spring manufacturer integrating,design and production. With 16 years of rich experience, its products are widely used in various industries such as mechanical equipment and electrical switches.

- Be-Cu Spring has a professional engineering team, and the technical engineer team has an average industry experience of more than 10 years. It focuses on innovative development of green and environmentally friendly products, and is committed to high-quality product quality.

- Focusing on the research and development of the production customization of fatigue-resistant springs, using imported raw materials from Japan, and strictly controlling the low-temperature tempering time in the production process, the service life of springs has increased by more than 20% compared with the same industry.

- Be-Cu Spring has a strict inspection system. Quality inspectors measure various indicators of the product in each process. The yield rate is controlled above 99.8%, and it has obtained international ISO certification.

- The spring has undergone surface strengthening treatment to remove surface impurities, which can make the surface structure stronger, smoother, and rust-proof. The effect is better and the service life of the spring is prolonged.

- The maximum frequency is hundreds of times per minute, suitable for the matching use of high-quality mechanical molds, and can meet the requirements of different customers

Specifications Of Beryllium Copper Precision Springs

| Structural Features | Cylindrical/Barrel/Open at both ends/Shrink at both ends/Conical/Hourglass/Closed at both ends/Both ends are ground/Fixed pitch/Variable pitch/Both ends are not ground |

| Wire Diameter Specification | 0. 08 ~ 8.0mm |

| Surface Treatment | Blackened/Galvanized/Nickel Plated/Shot Peening/Polishing/Dacromet/Anti-rust Oil/Electrolytic Polishing/Teflon Spray/Spray Paint |

| The Uses Of Metal Spring | Multipurpose |

| The Color Of Metal Spring | Customized |

| Lean Manufacturing Processes | Accurate Dynamometers and Projectors for Perfect Size |

| Various Materials | Various Materials To Meet Your Performance Requirements:Carbon Spring Wire SWC / Nickel-plated wire, galvanized wire / Piano wire SWPB / Copper wire, phosphor copper wire, beryllium copper wire / Stainless steel wire SUS301, SUS302, SUS304, SUS316, SUS631 /Square wire, flat wire, semi-circle wire / 65Mn _ / Alloy wire /82B / Other special specification steel wire /55CrSi (SWOSC-V) etc., |

| Firmly Packaged | Strong Packaging Is Not afraid of damage during transportation |