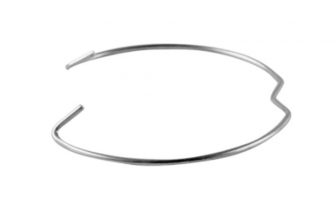

- Spring outer diameter: Custom

- Spring inner diameter: Custom

- Free height: Custom

- Whether standard parts: non-standard parts

- Material: Custom

- Steel wire diameter: Custom

- Pitch: Custom

- Rotation: a variety of options

- Shape: Custom

- Compressive strength limit: Custom

- Surface treatment: on anti-rust oil

- Load: Custom

- Times of use: 50000

- Clamping height: 1.8 (mm)

OEM Punching Special-Shaped Spring Sheet

Shaped spring is the main process equipment for industrial production. With the development of modern industrial products and the improvement of technical level, it depends to a large extent on the level of industrial development. From the perspective of spring structure, the development of special-shaped springs has roughly gone through four stages:

- The development stage of small special-shaped wire springs, disc springs, and nitrogen gas springs for molds. This is mainly due to the development of small plastic molds and large stamping molds.

- The main structural form of the special-shaped spring is a cylindrical wire spring with a circular section. At this stage, the mold industry mainly served industrial services such as automobiles, mining, machine tools and textiles, and recovered quickly after the war. The use of ordinary springs can meet the requirements of the mold.

- The application stage is the rise of special-shaped springs and square wire cylindrical spiral die strong springs. Therefore, the load-bearing deformation characteristics of the original cylindrical section common spring and the fatigue life under alternating load are difficult to meet the requirements of the mold, and rubber springs and square section springs appear.

- Application and development stage of special-shaped steel wire die spring. During this period, due to the development of electronic equipment, optical equipment and precision instrument products, the mold needs to develop in the direction of small size, high speed, and multi-station, thus promoting the development of powerful special-shaped springs. With the wider application of springs, the technical requirements for spring accessories and the diversity of products are also getting higher and higher.

Advantages Of OEM Punching Special-Shaped Spring Sheet

- Be-Cu Spring is a hardware spring manufacturer integrating,design and production. With 16 years of rich experience, its products are widely used in various industries such as mechanical equipment and electrical switches.

- Be-Cu Spring has a professional engineering team, and the technical engineer team has an average industry experience of more than 10 years. It focuses on innovative development of green and environmentally friendly products, and is committed to high-quality product quality.

- Focusing on the research and development of the production customization of fatigue-resistant springs, using imported raw materials from Japan, and strictly controlling the low-temperature tempering time in the production process, the service life of springs has increased by more than 20% compared with the same industry.

- Be-Cu Spring has a strict inspection system. Quality inspectors measure various indicators of the product in each process. The yield rate is controlled above 99.8%, and it has obtained international ISO certification.

- The spring has undergone surface strengthening treatment to remove surface impurities, which can make the surface structure stronger, smoother, and rust-proof. The effect is better and the service life of the spring is prolonged.

- The maximum frequency is hundreds of times per minute, suitable for the matching use of high-quality mechanical molds, and can meet the requirements of different customers

Specifications Of Punching Special-Shaped Spring Sheet

| Structural Features | Cylindrical/Barrel/Open at both ends/Shrink at both ends/Conical/Hourglass/Closed at both ends/Both ends are ground/Fixed pitch/Variable pitch/Both ends are not ground |

| Wire Diameter Specification | 0. 08 ~ 8.0mm |

| Surface Treatment | Blackened/Galvanized/Nickel Plated/Shot Peening/Polishing/Dacromet/Anti-rust Oil/Electrolytic Polishing/Teflon Spray/Spray Paint |

| The Uses Of Metal Spring | Multipurpose |

| The Color Of Metal Spring | Customized |

| Lean Manufacturing Processes | Accurate Dynamometers and Projectors for Perfect Size |

| Various Materials | Various Materials To Meet Your Performance Requirements:Carbon Spring Wire SWC / Nickel-plated wire, galvanized wire / Piano wire SWPB / Copper wire, phosphor copper wire, beryllium copper wire / Stainless steel wire SUS301, SUS302, SUS304, SUS316, SUS631 /Square wire, flat wire, semi-circle wire / 65Mn _ / Alloy wire /82B / Other special specification steel wire /55CrSi (SWOSC-V) etc., |

| Firmly Packaged | Strong Packaging Is Not afraid of damage during transportation |